In our company, we have several fully automatic punching and profiling lines. These allow us to easily and quickly form products from strip steel. At the moment, we mainly use this for decorative grilles, side panels and mounting brackets for the radiator industry.

How our punching and profiling lines work

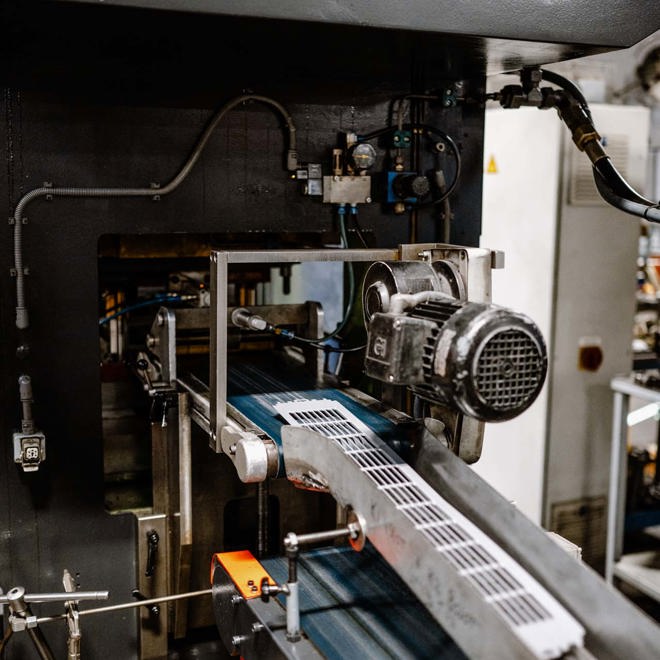

In Ulamo's punching and profiling lines, work is done from a roll of steel. The strip steel rolls off the belt almost directly through the machines. Pieces can be processed from 300 mm to about 3000 mm.

First, the material is punched by the punching machine. This punches the desired shapes out of the metal. After this, the material is profiled so that the shape of the metal itself can be machined. With this, for example, the edges of the metal can be bent up or down. A profiling machine does this with different sets of rollers through which the metal passes. Small cut-outs can also be made.

A flexible and automated process

Our punching and profiling lines operate fully automatically up to 200 tonnes. This makes it a fast and efficient way to process strip steel. In addition, we like to think along with you about creating the right shapes. We can adjust our machines in such a way that they can produce exactly the desired shape for you. As a result, you are very free to determine the shape and there are almost no restrictions.

Looking for an expert in metalworking?

Ulamo is happy to think along with you when it comes to machining different types of metal. Take a look at all our services or contact us directly.