Jan te Pas worked in the work preparation department at the DRU. He had been a sprayer himself and knew about paints. Apart from that, he kept homing pigeons behind his house. He kept his eyes and ears open and decided in 1961, at 50 and with a family of 10 children, to start his own business. He paid the start-up costs from the sale of a few champion pigeons. With the proceeds, he set up the first hall of Ulamo.

Let us tell you more about Ulamo and her history

In over 60 years, Ulamo has developed into a full-service powder coating company and a leading supplier to the radiator industry. Its consistently high quality, flexibility and no-nonsense approach has allowed Ulamo to grow into a successful company that serves customers across Europe.

1961

Ulamo - the Ulftse Lak- en Moffelbedrijf - was founded in 1961 by Jan te Pas. From the beginning, his sons were involved within the organisation, which later proved to be one of the keys to success.

1973

After reaching the limits of the expansion possibilities at the original site, Jan te Pas decided on a new building. There in Ulft, he unveiled the 'foundation stone' of the new office and production location in August 1973. Around this time, Jan te Pas went to Japan to learn about the 'electrostatic powder coating' technique. He soon decided to use this technique instead of the traditional wet-painting. Existing lines were converted and new powder coating lines were added.

1982

Besides the Netherlands, the rest of Europe, especially Germany, developed into an attractive market. In response to increasing demand, Ulamo opened a production site in Emmerich, Germany. This enabled faster growth in our neighbouring country.

1985

Ulamo 'De Rieze' was founded. This is one of Ulamo's paint shops still in operation today (in a modernised guise!).

1987

Ulamo is opening a third Ulft branch specifically focused on metalworking. More specifically, producing radiator components such as grilles, side panels, fronts and wall brackets.

1989

In 1989, metal production expanded by expanding the company's premises. This allowed several new production lines to be successfully installed.

1991

Ulamo Metaal starts its own production of radiator components. This later grows into its core business.

1994

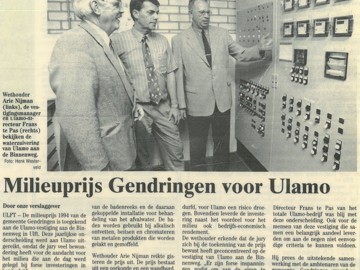

In the early 1990s, a new pre-treatment in the form of baths was built at the production site on Ettenseweg in Ulft, equipped with its own purification system. For this, Ulamo received the environmental award of the municipality of Gendringen and was nominated for the environmental award of the province of Gelderland. Products up to about 20 metres long can be treated without any problems.

Besides producing radiator components, Ulamo Metaal had many other product groups with varying degrees of success, including go-karts, engine mounts and copperware trading. Ultimately, supplying leading radiator manufacturers with metal accessories became the company's core business.

2001

In 2001 and 2002, Ulamo entered the newly built premises and factory hall(s) at Riezenweg in Ulft.

2003

The third Te Pas generation enters.

2008

One of the very successful innovations is radiator cladding for the residential market called Sentimo. A Sentimo radiator cover is made of metal that you simply place over an existing radiator. Installation takes just 5 minutes! With a choice of more than 50 colours and 3 different front panels, there is something for everyone. More information: www.sentimo.com

Nu

Today, Ulamo is divided into a coating division and a metal division. In addition, Sentimo -known among other things from national TV advertising- is the specialist in radiator cladding for the private market.

Ulamo stands for quality

The coating division masters a range of surface treatment techniques and offers the market all the necessary knowledge and experience in the field of high-quality technical and design coatings. The company holds the Qualicoat, Qualisteelcoat, Qualimarine and GSB certificates and conforms to the applicable Visem quality requirements, DIN, ISO and VMRG standards.

With over 60 years of experience in surface treatment, Ulamo brings colour, quality and durability to the conversion of aluminium, steel, stainless steel and hot-dip galvanised steel.

The metal division focuses almost entirely on the production of metal accessories for the radiator industry. This division has been developing innovative products - either in-house or in close cooperation with the customer - for many years.